- Author Henry Conors [email protected].

- Public 2024-02-12 02:45.

- Last modified 2025-01-23 09:07.

The K20A engine is a modern four-cylinder two-liter in-line gasoline engine manufactured by Honda Motor Co. Ltd. This type of motor is installed in many modern Honda car models. At the moment, this engine is the most high-performance and perfect serial "heart" of the brand "Honda".

K20A engine: specifications

As already mentioned, the unit is installed in cars with front-wheel drive. The compression ratio of this engine family varies from model to model. The volume is 2.0 liters, the number of valves is 16. The power depends on the car intended for installing the engine. The "strangled" version develops 150 hp. s., while the analogue for active and confident driving is 220 liters. with. The maximum torque remains virtually unchanged and ranges from 179 Nm to 206 Nm.

The stated maximum is reached at different speeds: from 4000 rpm to 7000 rpm. The electronically limited 8500 rpm is the maximum speed at which the two-liter K20A engine can operate. The technical characteristics of this unit are considered to bethe most perfect among competitors.

Location

"Where is the K20A engine number?" - many motorists ask this question. The fact is that finding this number is not so easy. You need to have some knowledge. For example, in order to understand where the K20A engine number is, you need to pay attention to the hole in the radiator grill, behind which the hood lock is located.

After that, with a flashlight, you should illuminate the part of the engine that is between the cylinder head and the radiator grille, and look through the hole in the grille at an angle of about 45 degrees. If it was not possible to see the desired engine number, you should contact the official service center with the appropriate question.

K20A engine: device

The location of the engine in relation to the car body is transverse, an in-line four-cylinder layout is used. The cylinders are numbered so that the first one is at the crankshaft pulley. The camshafts, by the way, there are two of them, are located on top. Liquid-cooled.

All K20A series engines are equipped with VTC variable valve timing and VTEC valve lift. The VTEC system, in turn, can be implemented both for both shafts, and only for the intake. This parameter is the main difference between K20A and K20A6 engines.

Cylinder block and cylinder head

Cylinder block cast fromaluminum alloy using GDC technology. In order to increase the rigidity of the main block, the main bearings are covered with a lower one-piece cover, which is attached to the block with 24 bolts. For cooling in the cylinder block, special channels are used through which the cooling liquid flows. In order to lubricate the pistons, crankshaft and connecting rods, as well as to supply oil to the oil nozzles, a whole system of special horizontal channels is used. The front of the block is equipped with a vertical channel in order to be able to supply oil to the cylinder head.

Cylinder head cast from aluminum alloy. The gas distribution mechanism is based on two camshafts (DOHC). The camshafts are driven by a chain connected to the crankshaft. The cylinder head also houses the camshaft bed. Rocker arms are installed in it, which are part of the VTEC system. The engine uses new advanced materials to reduce the mass of the springs and the likelihood of resonant vibrations.

Crankshafts and camshafts

The crankshaft is made of steel and has five bearings. When using a block of balancer shafts, eight counterweights are installed on the crankshaft. If there is no block of balancer shafts, then only four counterweights are used. Oil is supplied to the crankshaft through a special channel, which is carried out from the side of the main cylinder block. On the toe of the crankshaft of the engine are the gears of the drive of the gas distribution mechanism and the driveoil pump.

Each camshaft performs its own function: one of them drives the intake valves, the other - exhaust. The valves of the K20A engine and the clearance in their drive are adjusted using special adjusting screws. Each camshaft has five bearing journals. In order to lubricate the cams and journals with engine oil, it first enters the rocker arm for the VTEC system, then into special oil channels that are located on the camshaft in the second bearing journal. The valve timing on the intake valves is adjusted automatically and is carried out using the VTC system.

Timing chain and timing chain tensioner

The gas distribution mechanism in this type of engine is driven by a chain drive. There is a special tensioner that works due to oil pressure and automatically adjusts the tension of the timing chain. To eliminate unnecessary vibrations of the chain, there are special dampers that are installed on top and on the side. In order to reduce the amount of noise during the operation of the timing chain, the drive chain pitch has been reduced.

Cooling and lubrication system

The K20A engine is equipped with a closed-type liquid cooling system. Coolant circulation is forced. The belt used to drive the attachments also drives the coolant pump. thermostat withbypass valve, designed to maintain the optimum temperature of the cooling system, is located in the inlet pipe for the coolant. This device determines in which circle, small or large, let the liquid cool through the radiator.

The oil used to lubricate the engine undergoes full-flow cleaning and is supplied under pressure to the main moving parts and components of the engine. A trochoid type oil pump is used. Inside such a pump there are two rotors - leading and driven, their engagement is internal. And they rotate in the same direction. The pump is driven by a chain from the crankshaft. The oil filter is at the bottom in a horizontal position. The oil cooler, located between the oil filter and the cylinder block, serves to reduce the temperature of the oil that is supplied to the engine lubrication system.

Fuel injection into the K20A engine: device and characteristics

The fuel injection system used in this engine is the PGM-FI (or PGI - Programmed Fuel Injection) system, which allows sequential multipoint injection.

The installed fuel pressure regulator makes it possible to control the pressure under which, using a pump, fuel is supplied through a special filter to all injectors. In order to simplify the fuel system, save space and improve the reliability of the fuel injection system and its operation, fine and coarse fuel filters, a sensor for indicating the fuel level, and a fuel pressure regulator are located in the housingfuel pump.

Based on the readings of various sensors, the control unit regulates the amount of mixture needed for injection, the composition of this mixture and the ignition timing. In accordance with the readings of the oxygen sensor and the mixture composition sensor, which is installed in front of the catalyst in the exhaust system, the control unit can set various compositions of the fuel-air mixture. In addition, it calculates the amount of fuel supplied to the K20A engine per cycle, and does so in the following sequence:

- A decision is being made as to whether to inject fuel.

- Determination of the mode in which the vehicle is moving begins. For this mode, the position in which the accelerator pedal is located is calculated. The speed of the vehicle and the frequency with which the crankshaft rotates are also determined by reading the signals from the sensors.

- Starts a preliminary calculation of the amount of fuel injected, based on how fast the crankshaft rotates and on the readings given by the MAP sensor. At the same time, the best fuel economy parameters are achieved when driving in different modes.

- The control unit re-reads the signals from the sensors: throttle position, intake air temperature, coolant temperature, atmospheric pressure device, oxygen level, mixture composition, battery voltage, electro-pneumatic valve opening inrecirculation system. Based on these readings, corrections are made to the previously calculated amount of fuel.

- Final action - the control system gives a signal about how much fuel needs to be supplied to the system.

In order to increase efficiency, make sure that the fuel burns completely and for better atomization, special nozzles are used, in which there are 8-9 holes.

The control unit reads information from the camshaft and crankshaft position sensors in order to determine which of the cylinders it is necessary to supply the mixture at the moment, as well as the moment of injection.

The control unit is equipped with an overload protection function. This allows you to automatically stop fuel injection if the crankshaft rotates at a frequency that exceeds the maximum allowable. As a result of such manipulations, the engine speed drops.

Diagnosis

It is worth noting the diagnostic system that the K20A engine is equipped with. Characteristics and work process consists of the following items:

- The electronic control unit (ECU) is equipped with a built-in self-diagnostic system that continuously monitors the engine condition based on signals from various sensors. In the event of a malfunction, the system identifies it and alerts the driver by activating the Check Engine indicator on the instrument panel. In this case, the corresponding diagnostic code of the ISO 15031-6 standard and the codesmanufacturer directly to the computer memory.

- In order to read diagnostic codes, you need to connect a special scanner to the DLC connector. There is the possibility of deleting codes and reading Freeze Frame data using a scanner. The diagnostic connector is made according to the SAE standard, and the No. 7 pin is made according to the international ISO standard. This output has support for information exchange via K-LINE.

- When writing most of the codes, an algorithm consisting of two stages is used. It is used in such a way that at the first manifestation of a malfunction, its code is temporarily recorded in the computer's memory. If this malfunction reappears during the next operating cycle, then in this case the Check Engine indicator is activated. Driving Test No. 2 is carried out in the same way and with the same driving mode, but the prerequisite is that the ignition must be turned off between cycles.

- If any malfunction occurs, the conditions under which it occurred are recorded in the memory of the ECU (Freeze Frame).

Air intake systems and supplemental air supply

The intake manifold mounted on the K20A engine is located in front, between the radiator and the cylinder head. Graduation, on the contrary, at the back, next to the location of the partition of the engine compartment.

The supply of additional air to the nozzles is carried out using a separate system. The fuel injected into the engine goes through a stage of mixing with the supplied air, which helps the fuel evaporate better and cook more efficiently.fuel-air mixture. With this, a more uniform combustion process can be achieved, even if the mixture is lean. The result of these actions is to reduce the amount of hydrocarbons in the exhaust gases and make it easier to start a cold engine. A special valve is installed in the pipe of the cooling system, which regulates the air supply. The level of its opening is regulated depending on the change in the volume of paraffin, which, in turn, depends on the temperature of the liquid used for cooling.

Intake and exhaust manifolds, exhaust system

The intake manifold is made of aluminum alloy and can be equipped with a geometry change system. The exhaust manifold is made of steel to reduce weight.

In sports versions of Honda cars there is a special valve installed inside the muffler. It is used in order to reduce the reverse resistance during the release of exhaust gases. The valve is opened by pressure, which occurs at high speeds of rotation of the crankshaft. In this case, the exhaust gases exit the muffler without any resistance.

Oil Selection

Probably, every car owner is interested in the issue of changing the oil. What kind of oil to fill? The K20A engine responds most favorably to its native lubricant.

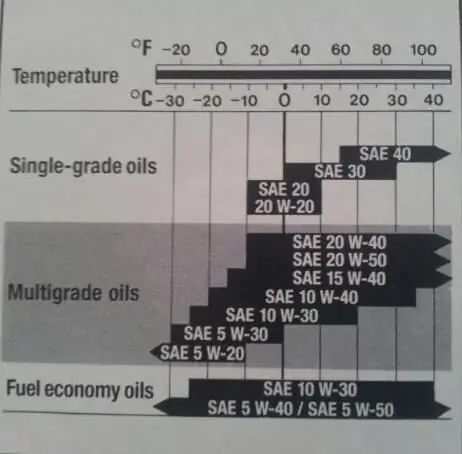

Because the K-family engines are high-revving, it is worth noting that the range of oils suitable for use is reduced to a minimum. In general, like any manufacturer,"Honda" recommends filling in oil of its own production. The characteristic of the oil being poured depends on the range of temperatures at which the car is operated. But if it is not possible to fill in factory oil, then some car owners recommend Mitasu or Zeppro Idemitsu products as a good alternative.

If suddenly there is a knock in the pan of the K20A engine, there is no reason to hesitate to contact the service center or the nearest competent service station. Most often, the problem lies directly in the wrong choice of oil, as well as inappropriate engine operating conditions.

Opinion of car owners

Due to the fact that Honda engines are famous for their reliability and high performance, the cars themselves have gained immense popularity among different age categories and segments of the population around the world.

If the user needs a compact minivan, then you can purchase "Honda Stream". The K20A engine, reviews of which are the most positive, is just the "heart" of this car. The dynamic performance and driving performance of this brand of car has made it one of the most popular family cars around the world. It's perfect for family picnic trips, visits and any long trip.

Another great car for a family with a large capacity uses the same engine - "HondaStepvagon". K20A allows even such a large and heavy minivan to confidently stay on the road and give odds to opponents.

If a car enthusiast is a young and ambitious person, or simply prefers speed and drive to boring driving, then Honda Integra or Honda Civic with the well-known Type R designation will easily suit him. These cars are famous for their reliability, increased rigidity bodywork and optimum stability. The increased level of dynamics is due to the installation of a 220-horsepower K20A.

The same powerful and reliable engine is used in a car designed for comfortable travel over long distances - the Honda Accord with a sporty character and Euro-R signature. In this configuration, the car is able to accelerate to the coveted “hundreds” in less than eight seconds!

In addition, it is worth noting that the Honda K20A engine is a great opportunity to increase the potential of almost any front-wheel drive car. Currently, it is a favorite tool for installation in VAZ cars of the tenth family. Most often, the owner of a domestic vehicle buys a K20A contract engine and installs it, changing the mounting system and adapting it to the technical needs of his car.